When designing the best product packaging, you may have come across the terms embossing and debossing. At this point, you might also be wondering about what these techniques are and the difference between them. Eventually, you will want to know which one works best for your custom packaging. So, debossing vs embossing? Let’s dive in.

The Difference

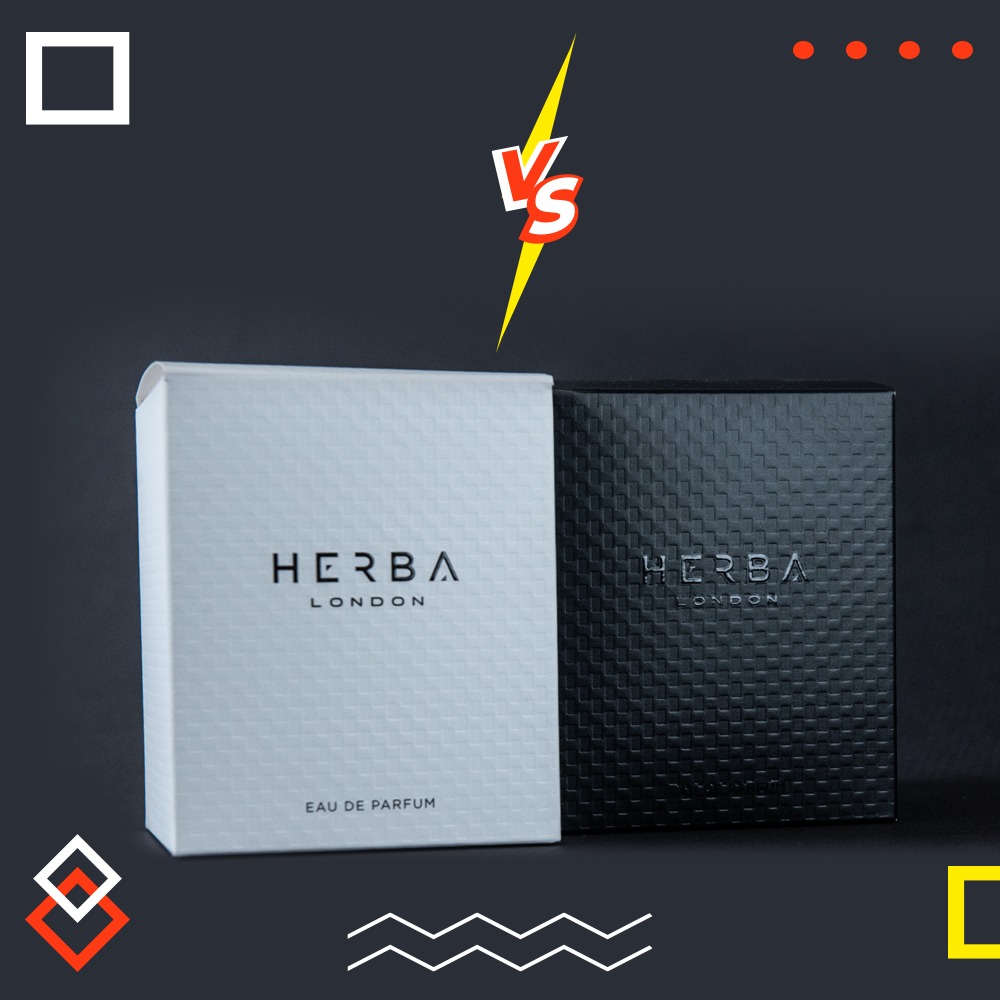

Basically, embossed printing separates the graphic (usually the brand logo) from the printed matter on the packaging. On the other hand, the debossing technique does the opposite of giving the graphic a sunken look.

For many products, such as jewelry items, it is clear whether to emboss or deboss the packaging. However, when it comes to custom packaging, the choice between debossing and embossing can depend on various factors.

So, what is the difference between embossing and debossing technique? In the simplest words, embossing creates an embossed design on the surface, and the debossing process will highlight that design.

Learn More About the Embossed Printing Process for Your Brand Logo!

The beginning of the embossed printing process will create a plate which is called ‘die’. The plate comes with a raised graphic that you want to emboss on your custom packaging. Then, the plate is pushed into the underlying product to raise the profile of the product design. This entire process will help you make your packaging stand out. Because the embossed die is made of metal, it will be highly durable. Even better, this plate can be used for both small and large projects.

You need to note that embossing your brand logo will be different than printing with raised ink. In addition, the embossing process is often expensive to set up. However, the quality is undeniable as it adds elegance and exquisite style to your packaging design.

What About the Process of Debossing Your Brand Logo onto Product Packaging?

The debossing process is quite similar to embossing. Yet, instead of stamping the bottom of the product packaging to make it stand out, the debossing process applies your brand logo from top to bottom. As a result, this will indent your brand logo on custom packaging. Even though this process is not as popular as embossing, debossed printing will create a unique look.

Debossing Vs Embossing – Improved Finishing Options By Adding Styles

The choice between debossing and embossing is actually a matter of taste. However, you will get the chance to customize the look with various wonderful finishing options. This way, you can further highlight and refine the style you are trying to convey.

For instance, you can customize the die to change the appearance of embossing or debossing. Doing this will make your packaging look like multiple layers of depth rather than a single raised layer. This allows the design to appear “formed” into your custom packaging.

Is Embossed Printing More Expensive Than Debossing?

If you use metal plates for both embossing and debossing processes to push your design into the material, you may be wondering why embossed printing is more expensive.

Well, it is clear that the embossed printing process requires an additional metal element. This element is famous as a “counter” in the printing industry. This is necessary actually to push the die down to the material. Using counters will surely increase the setup costs. Of course, adding this initial cost to your product packaging may not be economically desirable. This applies especially if you only need a small amount of custom packaging.

However, if you will see the final result, you will know that it is well worth it! For example, wouldn’t you love it to have appealing custom embossed boxes? Surely you will!

Embossing and Debossing – The Perfect Ways to Add More Dimensions to Your Packaging Design

Both embossing and debossing are two common but effective printing techniques in the packaging industry. Each technique will add a premium look to any medium. The two techniques can eventually make the image stand out and add depth, visually and physically. As a result, this added class element will let you create a more memorable touchpoint with customers.

Ideal for logos and names, embossed printing is a popular feature for luxury packaging, wedding invitations, business cards, and more.

Embossed Printing – Things To Keep In Mind When Applying This Technique

If you are interested in designing your packaging with embossed printing, you will need to consider some important things. What are they? Read on!

The Vector Graphics Are Ideal

The vector graphics are ideal for packaging designs with embossing and debossing. This is because the data in these files allow extrapolation up to the third level. This is done without sacrificing quality. This simply means that this data will be transferred to the die much better.

Focus On the Back of the Board Or Surface

Depending on the thickness of the material used, the embossed printing technique might leave an engraving on the back of the material. However, thicker materials are less likely to show through this engraving.

As mentioned above, the embossed printing process pushes the design into the material from the back. Thus, whatever happens, the opposite design remains on the back. If this is a problem, you should consider adding a support lamination or incorporating it into your design.

Thicker Paper Is Better

Thicker paper will be the best option for embossed areas. The thicker the paper stock you use, the more detailed the die press will appear on your custom packaging.

Multi-Level Embossing Might Add Complexity

The multi-level embossed printing design will look great. However, it might add complexity to both the packaging design and production.

If the depth of an area that is too small is too large, cracks are more likely to occur. Well, this will not be a good sign. To tackle this issue, you should consider using a multi-level embossed design.

Always Keep Your Packaging Design Simple

The embossed printing will add another dimension to your packaging design. Thus, you should not overdo it. Instead, you should always keep your packaging design simple.

This innovative technique will work perfectly to highlight:

- Your brand name

- Your business slogan

- Simple image and brand logo

- Watermark

- Small and simple patterns

Overly complex embossed or crowded designs that use embossing will only obscure the embossing itself and remove more than add.

Thus, you should consider combining the right color with embossed printing as a design method to add complexity. This will work better rather than embossing a crowded design.

For example, you can apply embossed printing to your cosmetic boxes. This will let you present your cosmetics proudly. In the end, you can grow your customer base with lovely cosmetic boxes. How? Check out here for more details!

How To Grow Your Customer Base With Creative Cosmetic Packaging Ideas

Debossing Vs Embossing – What Are the Benefits?

Detailed embossing and debossing not only show the special consideration of your product packaging. More than that, the two techniques will also enhance customers’ appeal. But what exactly can these techniques do?

Display Your Brand Logo Stunningly on the Packaging

If you want your brand logo to stand out, debossing or embossing will be the best option. The techniques will make your brand logo pop up on your custom packaging. Even better, they will give it a unique feel compared to other brands. For example, you can try out having custom debossed boxes. After all, we know that memorable brands are likely to succeed in winning the customers’ hearts. So, why wouldn’t you make your brand memorable in customers’ minds?

Highlight Your Product Details

With evocative packaging design, you can get your customers’ attention without any hassle. Embossing and debossing techniques on custom packaging will let you highlight all important information such as product details and your contact information. This way, you can turn more heads to pay more attention.

Make Your Custom Packaging Visually Appealing

Perhaps you find your custom packaging to be visually exciting enough. But do you know that adding textures creates a more attractive design? Both embossing and debossing techniques for custom packaging will allow customers to feel a perceptible experience. For example, your product will surely look more dazzling if you pack it in a captivating custom UV box.

Help You Increase Perceptual Value of Your Products

Customers unknowingly associate your higher prices with the quality of your products. Embossing and debossing techniques are two processes of communicating with customers. You’re your product packaging can do this by showing them beautiful designs and demonstrating that you have high standards in manufacturing.

Customers who see this level of care from your brand with something as simple as packaging are more likely to buy your products.

In Summary

Debossing vs embossing; which one will work best for custom packaging? The answer relies completely on how you want your custom packaging to be. Well, isn’t that what every brand wants? However, both these techniques will surely help your products get noticed by the market customers.

embossed printing separates the graphic (usually the brand logo) from the printed matter on the packaging —- true.